Formbox Vaccum Former – Realising Professional-Grade Products

Vacuum forming has lately become one of the best forms of manufacturing for those who belong to the non-technical crowd since it is based on a simple process: just heat the plastic and create a shape that can be replicated in multiple avatars.

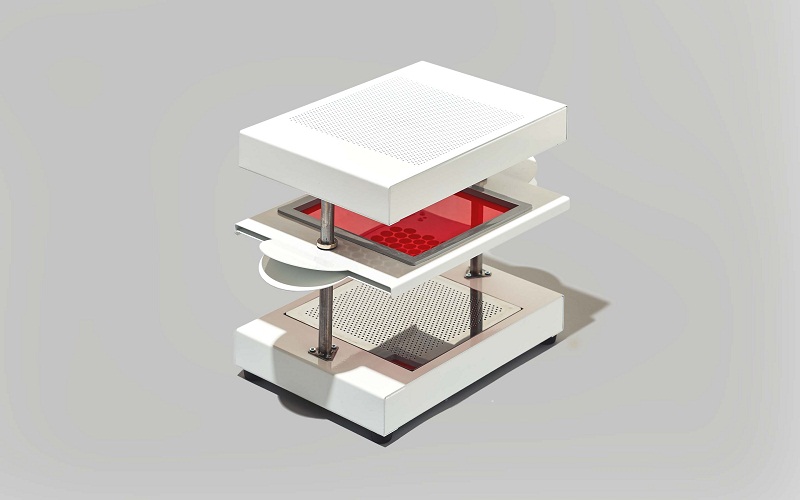

With the vacuum forming experience and featuring a user-friendly interface, Mayku, a London-based design company has created a device, especially for professional developers and weekend tinkerers to create professional grade products with the help of the FormBox vacuum former.

The Working Process

Powered by suction of an existing vacuum cleaner, the FormBox brings all elements together required for thermoforming process in a user-friendly design that also includes a heating element within.

It works similar to the MakerBotwhich is known to create thousands of 3D printable designs. The creators can also build an online library of designs along with systematic projects that can bridge the gap for people to start manufacturing projects soon after the box is opened.

One can create simple forms from all sorts of items including plasticine while also creating complex creations using 3D printers, laser cutters and the like. Here is a device that can help you make projects as soon as you get it shipped to your home. One just has to add the vacuum cleaner to the mix.

The Idea Behind FormBox

The FormBox is a quick reminder to the attributes of a sheet of hot plastic that is difficult to get made with 3D printing. The makers have introduced custom molds for chocolate, terrarium lids, cacti planters, and even some architectural models and RPG tiles that need a professional manufacturing approach.

The forming and molding process is pretty straightforward. But those who are inexperienced with the process will find it refreshing that it is an easy tool for prototyping, creation of small parts, or production of molds for secondary products.

The product is geared to become the “modern maker” for designers who are incredibly tech-savvy but lack the manufacturing finesse required for large scale productions. Since it is just powered by a vacuum cleaner, it can work for multi-mode users, and with the plethora of online library of projects, users can work to share or sell. A cool 3D printed design which is printed can be replicated easily is very scalable and sellable with the forming process.

The small “maker” business with online platforms like Etsy and Instructables along with 3D printing technology has changed the course of manufacturing processes. These tools have aligned together to be achievable to people who are not formally trained but do have the required vision to make something useful.

Benefits of FormBox and the Vacuum Forming Experience

Wit the vacuum forming process, design and production elements have become increasingly democratic and simplified. The team makes the process simpler with small forming tools and enough DIY vacuum plans that would help each and everyone to realize their vision.

Campaign on Kickstarter

Having already raised nearly $200K on Kickstarter within some days of their month-long campaign, Maykuhas ushered in plans to expand their fantastic product line for desktop injection and devices for rotational molding, too. The team has spelt out potentially profitable uses of the process and since it isn’t hard and expensive, the plan is appealing to all those who are well in the path of small scale manufacturing that entrepreneurs have not yet encountered.

Expect the revolution to hit the nerve of the small scale entrepreneurs as each of them bring their vision to the fore, to create innovative products easily and efficiently.